- 产品介绍

- 售后服务

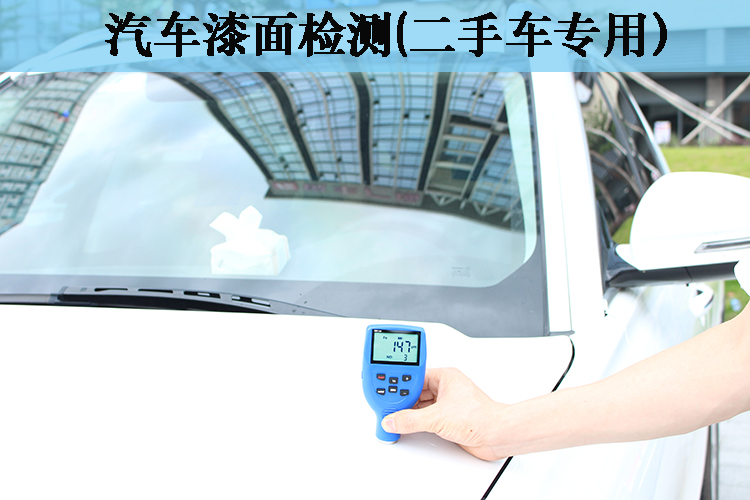

DR130一体式涂层测厚仪/蓝牙漆膜测厚仪(铁铝两用型 汽车专用款)

DR130涂层测厚仪是一款一体式两用测厚仪,按照国家行业:JJG818-2005标准专业测量金属材料表面涂镀层覆盖层物体厚度的专业无损检测仪器,使用简单,携带便捷,重复性更好,性能犹佳。它根据金属基体不同使用以下不同的测量方法。

A.磁性测厚方法,可无损地测量磁性金属基体(如:钢、铁)上非磁性覆层的厚度(如:镀锌、铬、锢、珐琅、橡胶、粉未、油漆、电泳、搪瓷、防腐层,喷塑,涂料等)

B.涡流测厚方法,可无损地测量非磁性金属基体(如:铝、铜、不锈钢)上非导电覆层的厚度(如:油漆、粉末、塑料、橡胶、珐琅、搪瓷、电泳、防腐层,喷塑层等)

本仪器能广泛地应用在汽车油漆,二手汽车评估,制造、金属加工、化工、商检等检测领域。

DR130涂层测厚仪仪器特点

A、采用合金一体化探头,牢固不易损坏

B、操作简单,测试速度快,灵敏度高

C、精美人工学一体化设计,携带方便

D、两种测试方式:连续测试(CONT INUE)和单次(SINGLE)测量方式

E、统计功能:最大值(MAX)、最小值(MIN)、平均值(MEA)

F、可存贮2000个测量数据(10组数据)

G、可以连接电脑进行通信读出存贮数据进行保存或打印(可选配)

H、两种校准方式:零点校准和二点校准

I、操作过程有蜂鸣声提示(单次测量方式)

I、自动识别铁基和非铁基底材

J、低电压指示

K、手动/自动关机功能

L、超大液晶屏背光显示,具有屏幕旋转倒置功能

M、公英制转换功能um/mil

N、支持蓝牙互联,实时手机APP同步数据(须定制蓝牙版)

DR130涂层测厚仪仪器特点

A、测量范围:0-1500μm

B、使用环境:温度:0℃-50℃,湿度:20%RH—90%RH,无强磁场环境下使用

C、最薄基体:0.4mm

D、测量精度:±(3%H+1.5μm)

E、分辨率:0.1μm /1μm

F、最小曲率凸5mm;凹25mm

G、最小测量面积:18*15mm

H、电源:三节(7号)碱性电池

I、外形尺寸:126mm*64mm*28mm

J、重量:106g(不含电池)

DR130涂层测厚仪仪器特点出厂清单:

序号 | 物品名称 | DR130(标准配置) |

1 | DR130涂层测厚仪主机1个 | √ |

2 | 校准膜片(49,100,250,370μm)共4片 | √ |

3 | 铁基体1块 | √ |

4 | 便携仪器包1个 | √ |

5 | 七号电池3节 | √ |

6 | 说明书1本 | √ |

7 | 合格证1个 | √ |

8 | 清洁布1块 | √ |

9 | 可定制蓝牙版测厚仪 | 适用于蓝牙版主机(选配) |

测漆仪,验车神器漆膜仪,DR130涂层测厚仪在二手汽车检测方面得到广泛应用。

蓝牙版涂层测厚仪:蓝牙APP功能特点

A、手机APP同步数据,实时显示测量结果

B、真人语音播报,无需分心看数据

C、中文/英文界面,优越的用户体验

D、单位设置:可添加编辑单位

E、报警功能,自动统计最大值(MAX)、最小值(MIN)、平均值(MEA)

F、测量数据分组保存,可添加删除产品及分组命名,测量工件时可在首页选择产品名称

G、可查看及发送保存测试记录,可根据月份查询测试记录,选中记录长按可删除记录

H、测量结果存储及实时发送到QQ,微信,电脑,可生成报表及打印

=============================================================================================

DR130 Coating thickness gauge

DR130 Coating thickness gauge is a professional measurement of metal material surface coating layer thickness of the major object of non-destructive testing equipment. According to the different metal substrates using different measuring methods.

A、Magnetic thickness method, can be nondestructively measuring magnetic metal matrix ( such as: steel, iron, nickel ) on non magnetic coatings thickness ( such as: galvanized, chrome, paint, electrophoresis, enamel, rubber, powder coating, enamel, etc.)

B.eddy current thickness method, can be nondestructively measuring non-magnetic metal substrate ( such as: aluminum, copper, stainless steel ) of non-conductive coating thickness ( such as: paint, powder, plastic, rubber, enamel, enamel, coating etc.)

DR130 Coating thickness characteristics

Characteristics of DR120 coating thickness gauge instrument

A, the use of alloy integrated probe, the world's leading technology

B, simple operation, fast testing speed and high sensitivity.

C, exquisite artificial integration design, easy to carry.

D, two test methods: continuous testing (CONT INUE) and single (SINGLE) measurement.

E, statistical functions: maximum (MAX), minimum (MIN), average (MEA)

F, which can store 2000 measurement data (10 sets of data).

G, can connect to the computer for communication, read out and store data for preservation or printing.

H, two calibration modes: zero calibration and two point calibration.

I, there are beep prompts in operation process (single measurement mode).

I, automatic identification of iron-based and non-ferrous base materials

J, low voltage indication

K, manual / automatic shutdown function

L, super LCD display backlight, with screen rotation inversion function.

M, Unit conversion μm/mil

Technical parameters:

1、Measuring range:0-1500μm

2、Using environment: 0℃-50℃and 20%RH—90%RH,not strong magnetic place.

3、the thinnest matrix: 0.4mm

4、measurement accuracy:±(3%H+1.5μm)

5、resolution ratio:0.1μm /1μm

6、minimum curvature:bugle5mm;concave25mm

7、minimum matrix:18*15mm

power: three (7) alkaline battery

8, size: 126mm*64mm*28mm

9, weight: 106G (excluding battery)